Electrical Supply System

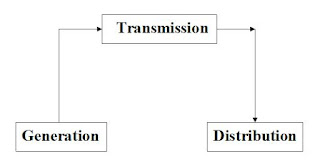

We call the network through which the consumers get electricity from the source as electrical supply system. An electrical supply system has three main components, the generating stations, the transmission lines and distribution systems. Power generating stations produce electricity at a comparatively lower voltage level.

The step-up transformers connected at the beginning of the transmission lines, increase the voltage level of the power. Electrical transmission systems then transmit this higher voltage electrical power to the possible nearest zone of load centres. Transmitting electrical power at higher voltage levels is advantageous in many aspects. High voltage transmission lines consist of overhead or/and underground electrical conductors. The step-down transformers connected at the end of the transmission lines decrease the voltage of electricity to the desired low values for distribution purposes. The distribution systems then distribute the electricity to various consumers according to their required voltage levels

AC Power Supply System

We usually adopt AC system for generation, transmission and distribution purposes. We use three phase 3 wire system for AC transmission and three phase 4 wire system for AC distribution. We can divide both transmission and distribution systems into two parts, primary transmission and secondary transmission, primary distribution and secondary distribution.

Primary Transmission

Here generating station produces three-phase power at 11KV. Then one 11/132 KV step-up transformers associated with the generating station steps up this power to 132KV level. The transmission line transmits this 132KV power to 132/33 KV step down substation consisting of the 132/33KV step-down transformers, situated at outskirts of town. The primary transmission is 3 phase 3 wire system that means there are three conductors for three phases in each line circuit.

Secondary Transmission

After that point in the supply system, the secondary power of 132/33 KV transformer gets transmitted by 3 phase 3 wire transmission system to different 33/11KV downstream substations situated at different strategic locations of the town.

Primary Distribution

The 11KV 3 phase 3 wire feeders passing through roadsides of the town carry the secondary power of 33/11KV transformers of secondary transmission substation. These 11KV feeders comprise the primary distribution of the electrical supply system.

The 11/0.4 KV transformers in consumer localities step down the primary distribution power to 0.4 KV or 400 V. These transformers are called distribution transformer, and these are pole mounted transformer. From distribution transformers, the power goes to consumer ends by 3 phase 4 wire system. In 3 phase 4 wire system, 3 conductors are used for 3 phases, and the 4th conductor is used as the neutral wire for neutral connections.

Secondary Distribution

A consumer can take the supply either in three phase or single phase depending on his requirement. In case of three phase supply the consumer gets 400 V phase to phase (line voltage) voltage, and for single phase supply, the consumer gets 400 / root 3 or 231 V phase to neutral voltage at his supply mains. Supply main is the end point of an electrical supply system.

Types of Electrical Supply Systems

DC Power Supply

Such type of supply supplies a constant DC voltage to the loads. It may deliver from a DC source or an AC source.

AC-DC Supply

AC energy can deliver DC power with the help of a rectifier, which converts the transformer output voltage to a varying DC voltage. The DC voltage passes through an electronic filter, which turns it into an unregulated DC voltage. There is also a register in series with the output to limit charging current and the final output power is fed to the load.

Switched Mode Power Supply (SMPS)

The main input is converted to DC voltage via rectifier and filter and then switched on and off at a high frequency (10 KHz- 1 MHz) by an electronic switch. It has a safety feature to protect the device and the user.

AC Power Supply

AC power supply can be taken from the main supply transferred to the desired voltage with the help of step up and step down transformer. This supply is divided into a single-phase and a three-phase system.

Losses in Electrical Power Distribution System

There are two types of transmission and distribution losses:

1. Technical Losses- The technical losses are due to energy dissipated in the conductors, equipment used for transmission line, transformer, sub- transmission line and distribution line and magnetic losses in transformers.

There are two types of technical losses.

a. Permanent / Fixed Technical Losses

Fixed losses do not vary according to current. These losses take the form of heat and noise and occur as long as a transformer is energized. Between 1/4 and 1/3 of technical losses on distribution networks are fixed losses.Example:-

• Corona

Losses

• Leakage Current Losses

• Dielectric Losses

• Open-circuit Losses

(b) Variable Technical losses

Variable losses vary with the amount of electricity distributed and are, more precisely, proportional to the square of the current. Consequently, a 1% increase in current leads to an increase in losses of more than 1%. Example:-

• joule losses in lines in each voltage level

•

impedance losses

•

Losses caused by contact resistance.

Main Reasons for Technical Losses

· Lengthy Distribution lines

· Inadequate Size of Conductors of Distribution lines

·

Installation

of Distribution Transformers away from Load Centers

Leaking

and loss of power

· Over loading of lines

· Abnormal operating conditions at which power and distribution transformers are operated

· Poor quality of equipment used in agricultural pumping in rural areas, cooler air-conditioners and industrial loads in urban areas

2. Non-Technical Losses (Commercial Losses)

Non-technical losses are at 16.6%, and related to meter reading, defective meter and error in meter reading, billing of customer energy consumption, lack of administration, financial constraints, and estimating unmetered supply of energy as well as energy thefts.

Electricity Bill

A consumer bill is reflective of the total cost incurred by the generation, transmission, and distribution companies in supplying power. A consumer’s electricity consumption is calculated on a monthly basis. The difference between current month’s reading and previous month’s reading provides the monthly electricity consumption by the consumer.

Components of Your Electricity Bills

- Tariff: When you receive your electricity bill, there are two things that you must initially look at - tariffs and category. There are two types of tariff codes - Low Tension (LT) and High Tension (HT). LT codes are usually used for personal offices and housing connections. HT codes are generally used for larger industries and complexes.

- Category: You must also check the category under which your connection falls. You must check whether your connection category is residential, industrial, or commercial.

- Fixed Charges(FC): FC is based on a consumer’s sanctioned load, which refers to the sum of the load of all electrical appliances within consumer premises. FC is levied to recover the overall cost of the network infrastructure laid by a DISCOM (poles, electric lines, electricity meters, etc.).

- Units consumed: Units consumed is nothing but the number of KWH (Kilo-Watt per hour) consumed in one month. If you keep a 100-watt bulb switched on for 10 hours, then there is a consumption of 1 KWH. The calculation of total units consumed is done on the basis of your electricity usage. Lesser the units consumed, lower will be your electricity bill amount.

- Energy Charge (EC): EC is calculated on the amount of energy consumed, and is levied to recover the cost of electricity purchased by the DISCOM.

- Connected Load and types of supplies: Connected Load is the total supply provided to the meter where the unit is in KWH. The connection load also determines if the connection will be a single or a three phase. Your supply will be three phases if the load is higher.

- Fuel Adjustment Charge (FACs): FAC is the extra cost of power which you generate due to increase in fuel prices. Since the fuel used mostly is coal, the production rates of coal are likely to decrease which means that FAC will increase.

- Tariff structure: Tariff structure is determining the rate at which the unit consumed is chargeable. It shows by how much the rates have increased depending upon the increase in the consumption.

- Fuel surcharge: The cost of generation may vary on a monthly basis even though the tariff structure may remain consistent. The surcharge is the change in the cost of electricity generation. The surcharge is applied per unit.

Electricity Tariff

The electricity tariff is defined as the rate at which the electrical energy is sold to a consumer.

However, the tariff should include the total cost of producing and supplying electrical energy plus the profit to the power company. In practice, the tariff cannot be same for all types of consumers because the cost of production of electrical energy depends upon the magnitude of electrical energy consumed by the user and his load conditions. Therefore, the tariff is fixed by considering the different types of consumers such as domestic, industrial and commercial, etc.

Types of Tariff

The various types of electricity tariff are defined as follows −

· Simple Tariff - When there is a constant rate per unit of electrical energy consumed, then it is called the simple tariff or uniform rate tariff.

· Flat Rate Tariff - When different types of consumers are charged at different fixed rate per unit of electrical energy consumed, then it is called the flat rate tariff.

· Block Rate Tariff - When a given block of electrical energy is charged at a specified rate and the succeeding blocks of electrical energy are charged at progressively reduced rates, then it is called the block rate tariff.

Components of Power(kW, kVA, kVAR)

KVA, KVAR, and KW are various types of power. I

- KVA means Kilo volt ampere. V*I*1000

- KVAR means Kilo Volt Ampere Reactive. V*I*Sinϕ*1000

- KW means Kilo Watt. V*I*Cosϕ*1000

where V is in volts

I is in Amps.

- Actual Power consumed by loads is called Kilo Watt Power.

- All the Power given to the load is not utilized as useful power, some power is being wasted. The power which is not consumed is called Reactive power i.e KVAR.

- whereas apparent power KVA is the vector sum of KW and KVAR.

i.e. VI = VICosϕ + VISinϕ (Added vectorially)

Active Power: KW

- Active Power is produced by Generators in power plants.

- Active Power is Consumed by resistive part of the loads. A pure resistive load consumes only active power.

- Example of Active power loads are Incandescent Bulbs, Heaters, Iron Box etc.

Reactive Power: KVAR

- Although Reactive power doesn’t do any work it is needed to create magnetic flux in the windings. Magnetic flux is responsible to produce Induction effects in electrical machines like transformers, alternators, and Induction motors.

Apparent power: KVA

- It is also known as demand, is the measure of the amount of power used to run machinery and equipment during a certain period.

Power Factor

The power factor of an AC power system is defined as the ratio of the Real or Active power absorbed by the load to the apparent power flowing in the circuit. Real power is the average of the instantaneous product of voltage and current and represents the capacity of the electricity for performing work.

P.F = Active Power(kW) x 100

Apparent Power(kVA)

Power Factor Improvement Methods

The low power factor due to inductive load is undesirable, which causes so many drawbacks in the power system. Hence, it needs to improve the power factor as nearly equal to unity. Power factor correction can be achieved by,

- Static capacitor- Power factor can be improved by connecting the static capacitor in parallel with the equipment operating at lagging power factor.

- Synchronous condenser- An over-excited synchronous motor running on no load is known as a Synchronous condenser. The over-excited synchronous motor takes the leading current and behaves like a capacitor. When it is connected across supply draws leading current partially or fully compensates for the lagging reactive components of the load current and thereby improves the power factor.

- Phase advancer- Phase Advancers are mainly used to improve the power factor of the induction motor.

Sanctioned Load means load in kilowatt (kW)/kilovolt ampere (kVA)/Horse Power (HP) for which the Distribution Licensee had agreed to supply from time to time subject to governing terms and conditions.

Contract demand is the amount of electric power that a customer demands from utility in a specified interval (Unit used is kVA or kW)

Maximum demand- The maximum demand of electricity ( kW or kVA ) requirement over a billing cycle is called as maximum demand.

Monthly Minimum charges (MMC) is minimum amount or unit for an electricity connection which is to be billed if the actual bill amount is less than MMC

Introduction to Transformer

A transformer is a device used in the power transmission of electric energy. The transmission current is AC. It is commonly used to increase or decrease the supply voltage without a change in the frequency of AC between circuits. The transformer works on the basic principles of electromagnetic induction and mutual induction.

Transformer Types

Based on Voltage Levels

Commonly used transformer types, depending on the voltage, are classified as

· Step-up Transformer: They are used between the power generator and the power grid. The secondary output voltage is higher than the input voltage.

· Step-down Transformer: These transformers are used to convert high-voltage primary supply to low-voltage secondary output.

Based on the Medium of Core Used

In a transformer, we will find different types of cores that are used.

- Air Core Transformer: The flux linkage between primary and secondary winding is through the air. The coil or windings wound on the non-magnetic strip.

- Iron Core Transformer: Windings are wound on multiple iron plates stacked together, which provides a perfect linkage path to generate flux

Losses in Transformer

The following power losses may occur in a practical transformer −

· Iron Loss or Core Loss

· Copper Loss or I2R Loss

· Stray Loss

· Dielectric Loss

In a transformer, these power losses appear in the form of heat and cause two major problems −

· Increases the temperature of the transformer.

· Reduces the efficiency of the transformer.

Iron Loss or Core Loss

Iron loss occurs in the magnetic core of the transformer due to flow of alternating magnetic flux through it. For this reason, the iron loss is also called core loss.

Copper Loss or I2R Loss

Power loss in a transformer that occurs in both the primary and secondary windings due to their Ohmic resistance is called copper loss or I2R loss

Stray Loss

In practical transformer, a fraction of the total flux follows a path through air and this flux is called leakage flux. This leakage flux produces eddy currents in the conducting or metallic parts like tank of the transformer. These eddy currents cause power loss, which is known as stray loss.

Dielectric Loss

The power loss occurs in insulating materials like oil, solid insulation of the transformer, etc. is known as dielectric loss. The dielectric loss is significant only in transformers working on high voltages.

Tips for Energy Saving in Transformers

Following are the energy conservation measures in transformers-

1. The load should always be given in the transformer according to the load marked on it, because when overloaded, the energy loss of the transformer starts.

2. The joints made on the transformer should be properly connected because if the joints are loose, there is a loss of energy for sparking.

3. The cooling system of the transformer should work smoothly.

4. The coolant oil etc. in the transformer should be checked from time to time.

5. New transformers should be installed in place of old transformers because energy loss is more in old transformers.

6. Service of transformer should be done from time to time.

7. In case of non- use, the transformer should be switched off (line cut), so that there is self running energy.

Electric Motors

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft.

Applications include industrial fans, blowers and pumps, machine tools, household appliances, power tools, vehicles, and disk drives. Small motors may be found in electric watches.

Types of Electric motors

There are two main types of electric motor: AC motors (alternating current) and DC motors (direct current).

AC Motors

AC motors use an alternating current to convert electrical energy into mechanical energy. They only require a low power upon start-up, and they allow for controlled acceleration, which means that they can retain a constant speed and performance.

DC Motors

All DC motors use a direct current, DC motors also have good speed control and a high starting torque. This makes them ideal for electric motor applications that need to move heavier loads in a variety of conditions, for example, wiper systems for rail, marine and haulage industries.

Losses in Induction Motors

There are three main types of losses in induction motors:-

1. Copper Losses

The copper losses occur in stator and rotor windings. This type of loss depends upon the current winding. This loss is also called electrical or I2R loss. The winding resistance is found by calculating the wire size and length. Multiplying this resistance by the square of the current, copper losses are determined.

2. Iron losses

This type of losses occurs in the stator and rotor cores of induction motor. This type of loss is also called core or magnetic loss. This loss consists of hysteresis and eddy current loss. Both these loss depend on supply frequency and on flux density in the core.

3. Friction and Winding Losses

These losses are due to the friction of the moving parts and due to the wind resistance. These losses are also called mechanical losses.

Features and characteristics of energy efficient motors

1. Starting and running torque is more.

2. Noise and vibrations are very very less.

3. Material used for its construction is of high quality having higher flux densities and current density.

4. Maintenance required is very less.

5. Power factor is better as air gap is precise.

6. High quality materials reduce the size of machine.